You must burn a lot of wood or plant matter to make a small amount of useable ash. The sieved, unwashed ash collected after a Winter burning my small wood furnace only gives me enough material to make a couple buckets of 50% clay 50% ash glaze. Furthermore, I burn whatever type of wood happens my way, and it often contains impurities like dirt and nails. So besides the limited quantity I have available, there is also a question of consistency.

Substituting part or all of real ash with synthetic ash in a glaze recipe is one method to address the problems of impurities, variability, and supply.

For most of these tests I just made a simple 50/50 mix of the synthetic ash recipe with a local stoneware body in order to compare to my previous real wood ash glazes. The following tests were all fired to Orton Cone 11 in reduction.

Robert Tichane’s Recipe

Robert Tichane’s excellent book Ash Glazes has a chapter devoted to synthetic ash glazes. Based on Dr. Emil Wolff’s analysis of Beech wood ash, Tichane creates the following synthetic ash:

Limestone: 75 g (43.2%)

Dolomite: 50 g (30.8%)

Potassium Carbonate: 25 g (15.4%)

Bone Ash: 6 g (3.7%)

Sodium Carbonate: 5 g (3.1%)

Calcium Sulfate: 3 g (1.9%)

Silica: 2 g (1.2%)

Sodium Chloride: 0.2 g (0.1%)

Ferric Oxide: 1 g (0.6%)

Robert Tichane’s Synthetic Ash 100%

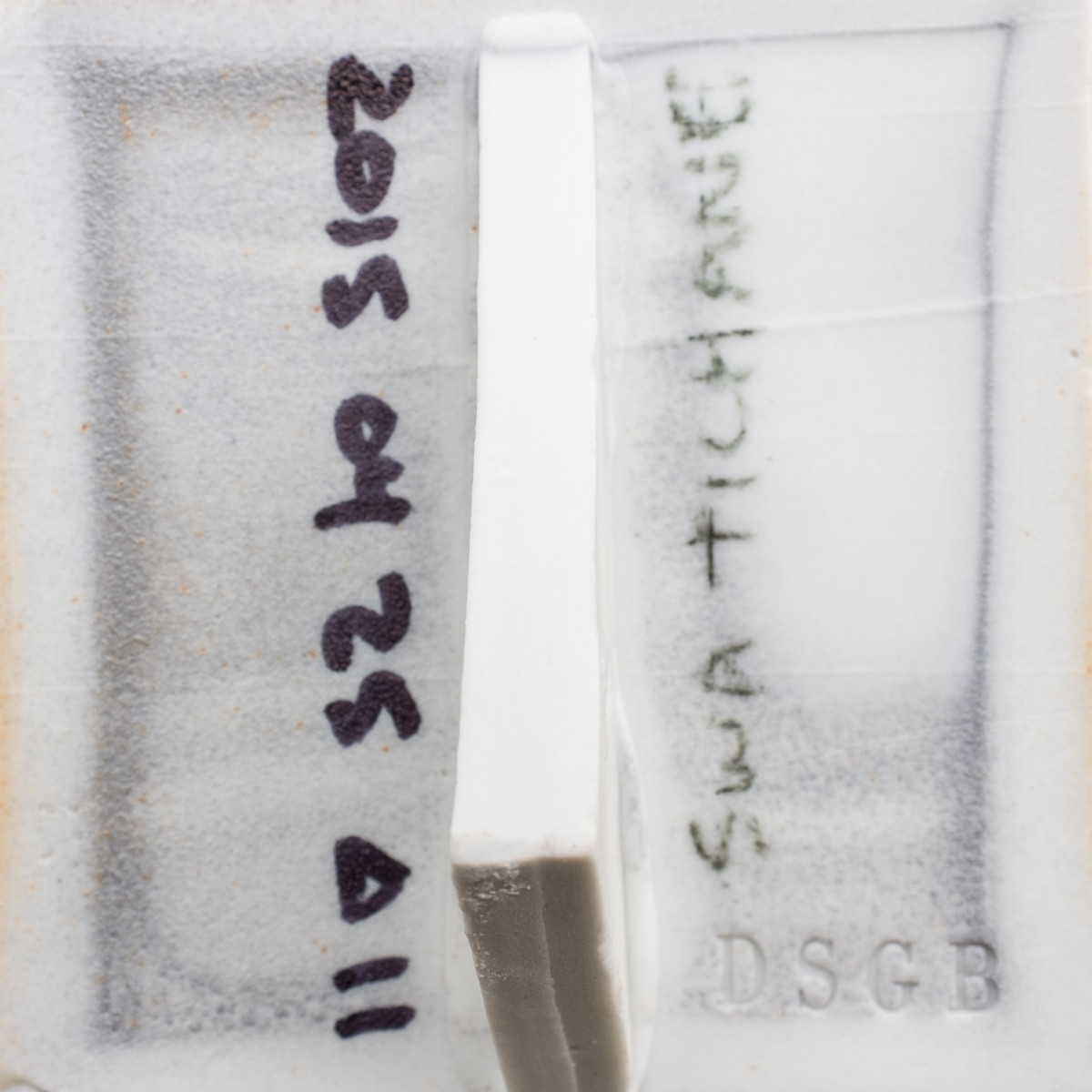

As you can see in the third picture, the soluble salts tend to permeate bisque ware, possibly decreasing body melting temperature and increasing warping. (It would be interesting to compare the effects of solubles on a raw-glazed tile.) Solubles are troublesome for other reasons, of course. Water should not be removed from an already mixed glaze batch, and safety is a concern.

Tichane Synthetic Ash 100%. Porcelain, Orton Cone 11 Reduction.

Tichane Synthetic Ash 100%. Stoneware, Orton Cone 11 Reduction.

Tichane Synthetic Ash 100%. Porcelain, Orton Cone 11 Reduction.

Robert Tichane’s Synthetic Ash 50%, Stoneware 50%

Tichane’s recipe is interesting because of the soluble components that emulate unwashed wood ash. And of all the synthetic ash recipes I tested, Tichane’s comes closest to the feel of real unwashed wood ash glazes.

Porcelain, Orton Cone 11 Reduction.

Stoneware, Orton Cone 11 Reduction.

Maritaro Onishi’s Recipe

Ash Glazes also contains a recipe for synthetic ash by Maritaro Onishi:

Limestone: 62%

Feldspar: 12%

Bone Ash: 7%

Magnesite (Magnesium Carbonate): 5%

Kaolin: 10%

Silica: 3%

Maritaro Onishi’s Synthetic Ash 50%, Stoneware 50%

Tichane notes that impurities in the feldspar and kaolin may add iron and manganese. However, in my test I added an additional 2% red iron oxide and 1.2% manganese dioxide.

Porcelain, Orton Cone 11 Reduction

Stoneware, Orton Cone 11 Reduction

Etsuzo Katou’s Recipe

John Neely on the Clayart mailing list mentions Etsuzo Katou who published another synthetic ash recipe, Ueda synthetic ash #3:

Whiting: 59%

Potash Feldspar: 22%

Magnesium Carbonate: 11%

Bone Ash: 5%

Red Iron Oxide: 2%

Manganese Dioxide: 1%

Etsuzo Katou’s Synthetic Ash 50%, Stoneware 50%

I accidentally used 2% Manganese in my test glaze.

Porcelain, Orton Cone 11 Reduction

Stoneware, Orton Cone 11 Reduction

Joseph Grebanier’s Recipe

In chapter 13 of Chinese Stoneware Glazes, Synthetic Wood Ash, Joseph Grebanier compares various wood ash analyses and questions the accuracy of Onishi’s synthetic ash formula. Using Herbert Sanders’ ash analyses in The World of Japanese Ceramics, Grebanier creates the following recipes:

Grebanier’s Batch Recipe for Synthetic “Common Ash”:

Whiting: 35.73%

Buckingham Feldspar: 24.35%

Kaolin: 10.39%

Flint: 10.11%

Magnesium Carbonate: 6.86%

Bone Ash: 4.09%

Soda Ash: 3.90%

Red Iron Oxide: 3%

Manganese Dioxide: 1.32%

Grebanier’s “Common Ash” recipe was later simplified by Phil Rogers in Ash Glazes:

Whiting: 36%

Buckingham Feldspar: 25%

Kaolin: 10%

Flint: 10%

Magnesium Carbonate: 7%

Bone Ash: 5%

Soda Ash: 4%

Red Iron Oxide: 3%

Manganese Dioxide: 1%

Grebanier’s Batch Recipe for Synthetic Pine Ash:

Whiting: 44.37%

Orthoclase: 36.17%

Magnesium Carbonate: 6.36%

Soda Ash: 4.38%

Bone Ash: 4.1%

Red Iron Oxide: 2.31%

Manganese Dioxide: 2.28%

Grebanier’s Pine Ash recipe was later simplified by Robert Tichane in his Ash Glazes:

Whiting: 44.4%

Feldspar: 36.2%

Magnesium Carbonate: 6.4%

Soda Ash: 4.4%

Bone Ash: 4.1%

Red Iron Oxide: 2.3%

Manganese Dioxide: 2.3%

Grebanier’s Synthetic Common Ash Recipe (simplified)

In the following tests I substituted Buckingham Feldspar for my local Potash Feldspar.

50% Stoneware, %50 Synthetic Ash. Porcelain, Orton Cone 11 Reduction

50% Stoneware, %50 Synthetic Ash. Stoneware, Orton Cone 11 Reduction

40% Stoneware, %60 Synthetic Ash. Porcelain, Orton Cone 12 Reduction

40% Stoneware, %60 Synthetic Ash. Stoneware, Orton Cone 12 Reduction